no data

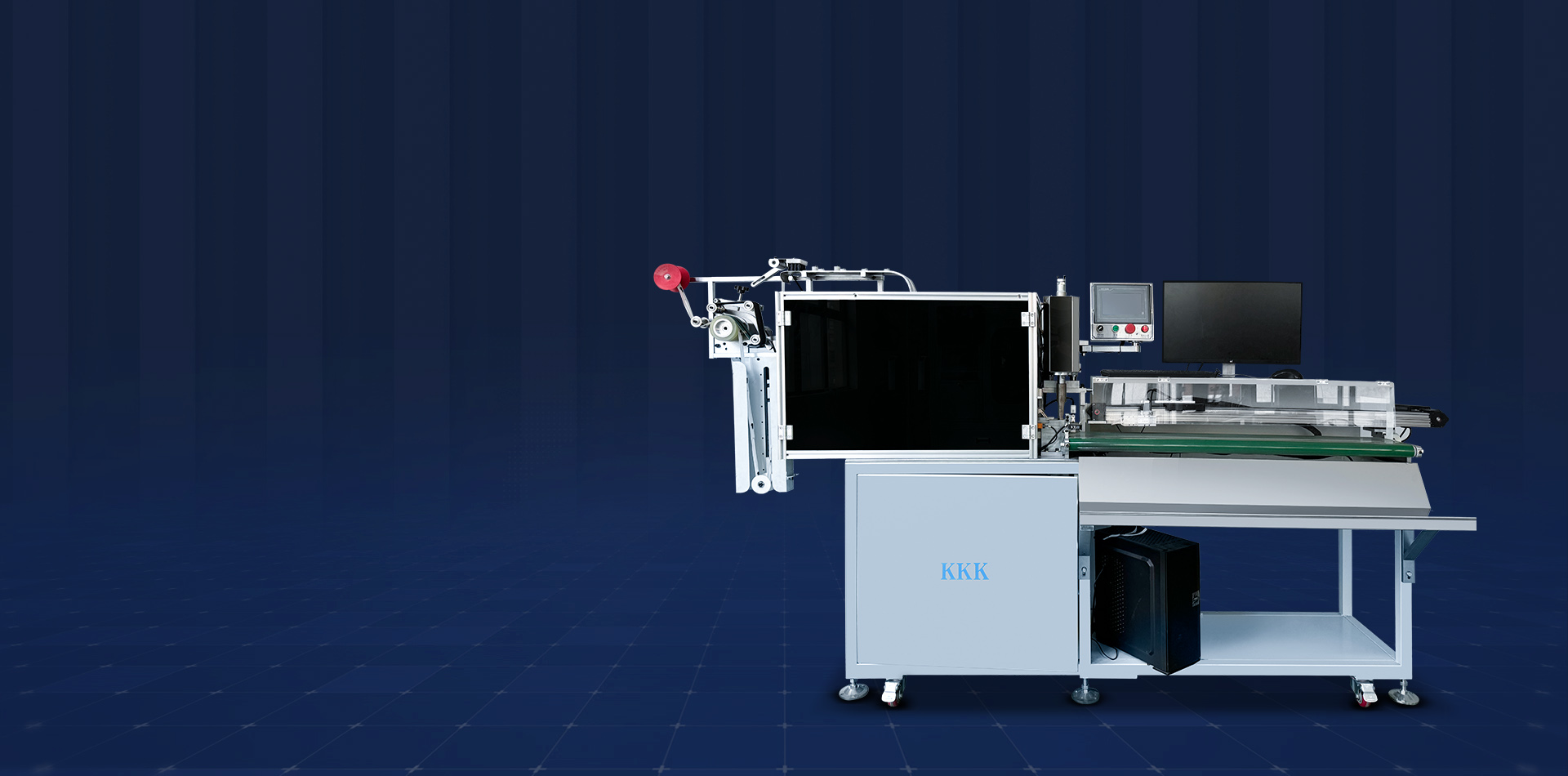

zipper machine

our products

Professional zipper machine manufacturer produces a wide ranges of zipper making machine since 2001.

Our company insists to the market demand as the guide, technology and innovation as the support, and customer service as the center, the extensive design talent, and actively promote the application of advanced technology, manufacturing high quality, high standard full set of zipper machinery and equipment.

no data

One-stop solution

Specialized OEM/ODM Services

We can customize the zipper making machine according to customer's demand. If customer have the drawing, which includes the dimensions, materials, special requirements, then we can make the mold according to the drawing.

About the after-sales problems of zipper machine, we can first help customers solve the problem through the video, but also can arrange the technician to the customer's factory to do after-sales!

![]() Technicians go directly to the customer's factory to do after-sales service

Technicians go directly to the customer's factory to do after-sales service

![]() Machine colors and logos can be customized

Machine colors and logos can be customized

![]() We have complete production line and testing equipment

We have complete production line and testing equipment

Our clients

We warmly welcome customers at home and abroad to negotiate cooperation and become your trusted partner to create a better future together.

no data

About us

We have our own team to research, design, produce and sell.

Wenzhou Jinlong Zipper Machinery Co. , Ltd is the zipper machine manufacturer of producing zipper machines and precision accessories parts with collection of development, production, sales and after service.

Our company insists to the market demand as the guide, technology and innovation as the support, and customer service as the center, the extensive design talent, and actively promote the application of advanced technology, manufacturing high quality, high standard full set of zipper machinery and equipment. KKK plants at every step, steady deveiopment, from a complete set. The whole series of products, a variety of high-end varieties are the counterparts of individual products R&D zipper machinery leader in China.

no data

WhaT'S NEW

Blog & article

Follow us to share how to choose and use zipper related products, as well as common questions about the products.

no data

Contact us to customize your zipper machine

no data

Useful Links

Products

Contact Us

Contact: Lucy Wang

Tel: +86-13626550672

Email: zippermachine88@gmail.com

WhatsApp: +86-13626550672

Company address: xianzhong industrial park, gulian industrial zone, qiaotou, yongjia, zhejiang, china, zip code: 325000

Copyright © 2025 Wenzhou Jinlong Zipper Machinery Co. , Ltd. - www.kkkzippermachine.com | Sitemap | Privacy Policy